- 一.介绍

- 二.快速入门

- 三.开发者支持

- 四.常见问题汇总

一.介绍:

1.1 箱行天下

箱行天下是深圳中集智能科技有限公司开发的用于集装箱追踪,数据监控的软件平台。为了满足用户对集装箱的集中管理需求,其功能涵盖:集装箱温度湿度监控,集装箱路径记录,冷藏集装箱电量控制,冷藏箱冷机状态监控,冷藏箱开关控制,远程设置冷藏箱设定温度,箱门开关检测,数据异常报警,设置预警提醒并推送微信通知。箱行天下的优势包括如下几个方面。

(1)增强可见性:集装箱追踪提供了对集装箱位置和状态的实时可见性。这种可见性使企业能够在供应链的每个阶段监控和追踪集装箱,从而实现更好的计划、协调和决策。它提高了运营效率,并通过提供有关货物状态的准确信息来增强客户服务。

(2)提高安全性:追踪集装箱有助于减轻安全风险。通过实时追踪,企业可以迅速发现任何未经授权的集装箱的行为。他们可以立即采取行动防止损失,开展调查,并加强安全措施。集装箱追踪系统包括地理围栏和安全警报等功能,以确保货物的完整性和安全性。

(3)高效的资源配置:集装箱追踪优化了资源配置。通过了解集装箱的精确位置,企业可以高效地分配劳动力、设备和存储设施。他们可以规划和优化路线,减少空集装箱的运输次数,并更好地利用可用的运输能力。这降低了成本,并增强了整体运营效率。

(4)供应链优化:追踪集装箱使企业能够优化其供应链运营。对集装箱运动的实时可见性有助于识别物流过程中的瓶颈、延迟或中断。这使企业能够主动解决问题,及时调整,并保持供应链的顺畅流动。优化会导致规范交货时间、减少库存持有成本和提升客户满意度。

(5)基于数据的洞察力:集装箱追踪生成大量可分析的数据,以获得有价值的洞察。通过分析追踪数据,企业可以识别模式、趋势和改进的领域。他们可以优化航线,识别供应链效率低下的地方,并做出基于数据的决策。这些洞察力促进持续改进和更好的战略规划,最终实现成本节约和运营效率提升。

(6)风险缓解:集装箱追踪有助于减轻与运输和物流相关的风险。通过实时监控集装箱,企业可以预测和应对潜在的延迟或中断,例如恶劣的天气条件或港口拥堵。他们可以采取积极措施来减轻风险,降低不可预见事件的影响,并确保货物的顺畅流动。

1.2 产品介绍

深圳中集智能科技有限公司生产的集装箱智能设备可读取,管理,监测集装箱各方面的数据,与箱行天下搭配使用,形成闭环的物联网系统,提高箱东货主的运营管理效率,最终增加企业利润。

深圳中集智能科技有限公司的"电子通风器"是一种集装箱智能设备,旨在为集装箱提供实时监测和数据收集功能。它可以安装在集装箱通风口处,与深圳中集智能科技有限公司的箱行天下平台相连,提供全面的远程监控和数据分析。

"电子通风器"设备的主要特点和功能包括:

实时位置和运动监测:通过集成的定位系统和加速度计,"电子通风器"设备能够提供实时的集装箱位置和运动信息。这使得企业可以随时跟踪和监测集装箱的准确位置,了解其在供应链中的实际状态。

温度传感器:"电子通风器"设备还配备了温度传感器,可以监测集装箱周围的温度。这对于运输货物尤为重要,可以确保货物在适宜的环境条件下运输。

数据分析和报告:通过与深圳中集智能科技有限公司的物联网平台连接,"电子通风器"设备收集的数据可以进行实时分析和报告。这些数据可以用于优化供应链运作、提高物流效率,并提供有价值的见解和决策支持。

“冷箱卫士”设备的主要特点和功能包括:

温湿度传感器:“冷箱卫士”设备配备了温湿度传感器,可以采集集装箱内的温湿度数据。温湿度监控在冷链运输中发挥着重大的作用,它能有效提高货物管理的效率和力度。降低货物运输中的腐坏风险。

报警和警报功能:“冷箱卫士”产品具备报警和警报功能,以帮助用户及时应对潜在的问题。例如,当温度或湿度超出设定的安全范围时,产品会推送警报通知用户。这使得用户可以立即采取措施,防止货物受损。

数据分析和报告:“冷箱卫士”产品与箱行天下平台连接,可以收集、存储和分析运输数据。这些数据可以用于生成报告和分析,帮助用户了解冷藏箱的运输情况、运输效率和供应链绩效。

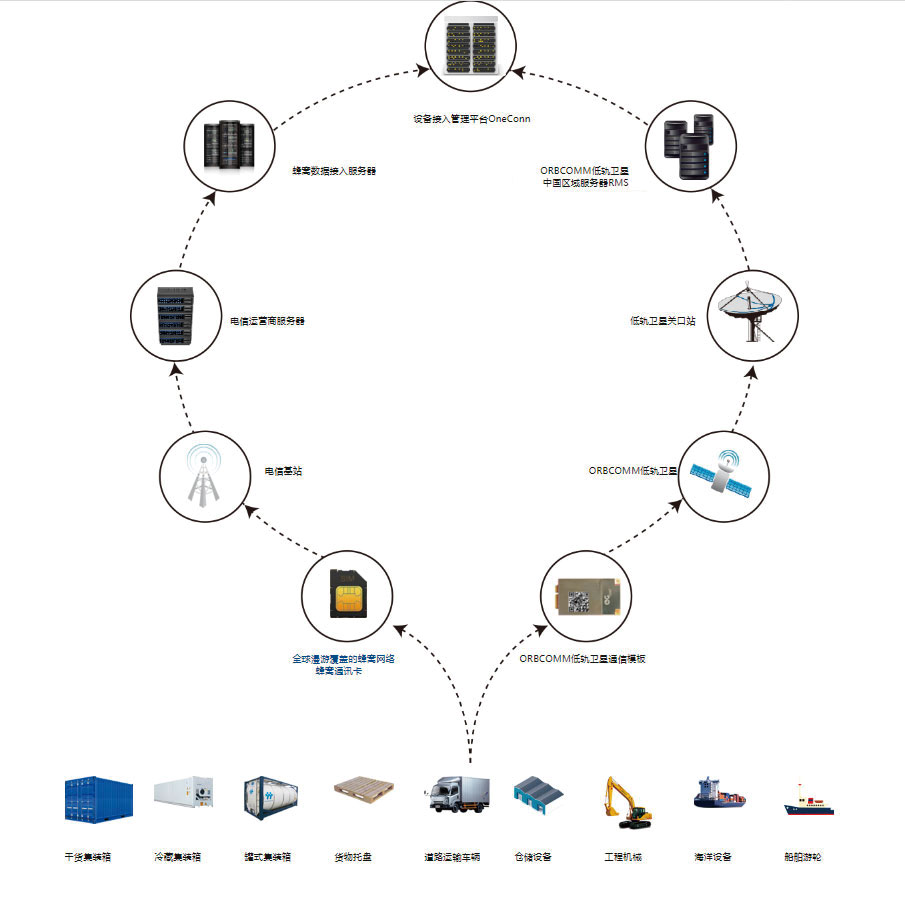

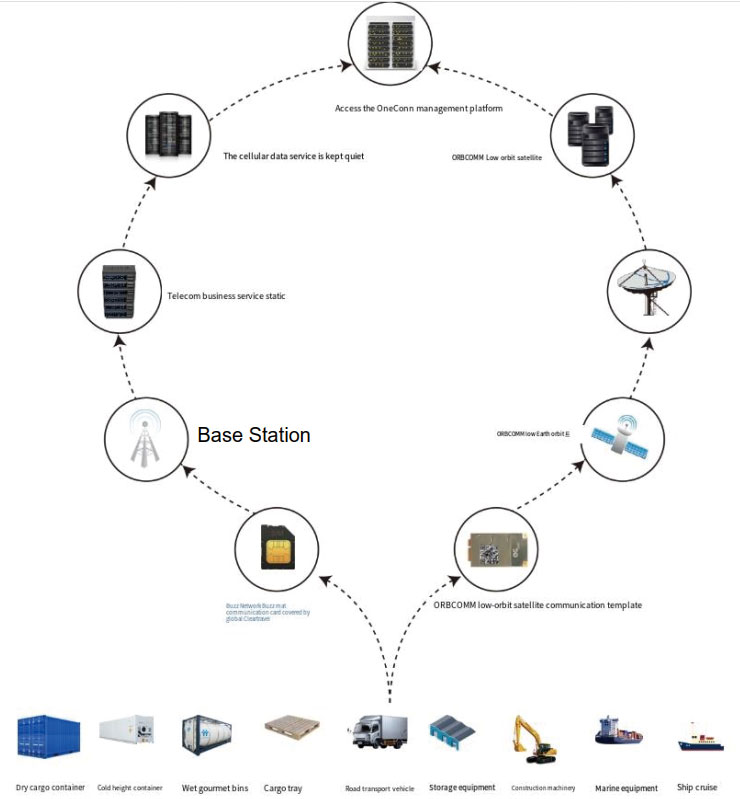

1.3 数据通道

我们的产品支持两种数据上报方式:基站和卫星。基站方式适用于在城市或者有较好网络覆盖的地区使用,它能够通过无线网络将设备数据实时上报至平台数据库。而卫星方式则适用于偏远地区或者网络覆盖较差的地方,通过卫星通信将数据传输至平台,确保数据的稳定和可靠性。

我们的平台数据库具备强大的数据管理和处理功能。它可以接收和存储来自各种智能设备的数据,并进行实时的数据分析和处理。通过我们的用户友好型界面,您可以轻松访问和管理设备数据,监控设备状态,以及生成详细的报告和分析结果。同时,我们的平台还支持数据的导出和共享,方便与其他系统或合作伙伴进行数据交换和共享。

我们的产品可以满足企业和组织的需求。无论是环境监测、物流追踪、农业管理还是工业自动化,我们的解决方案都可以提供可靠的数据管理和分析支持,帮助您实现更高效、更智能的业务运营。

二.快速入门

2.1 搜索箱号

搜索栏在页面的左上角处,输入箱号进行搜索。搜索功能支持模糊搜索,输入部分箱号关键字可从下拉候选项中查看系统中记录的包含关键字的结果,点击候选项可定位到该结果。

2.2 查看数据

在实时数据菜单中,搜索要查看的箱子。点击该箱子可在左侧详情页弹窗中查看具体的集装箱数据,包括集装箱编号,箱子最新位置,箱子最新温湿度(温湿度曲线),冷藏箱冷机开关状态,箱子当前的定位方式,箱子的运动状态(静止/运输中)

2.3 绑定微信

在成员管理菜单中,用户可将箱行天下平台账号与自己的微信进行绑定。

绑定方法:

(1)点击账号旁的“绑定微信”按钮

(2)打开手机微信扫描弹窗中的二维码

(3)选择头像和昵称

(4)完成绑定

解绑方法:

(1)点击账号旁的“解绑微信”

(2)点击确认

(3)完成解绑

箱行天下账号最多允许绑定一个微信账号,同样,微信账号最多允许绑定一个箱行天下账号

绑定微信后可开启微信消息通知,接收箱号的报警提醒(如温度过高提醒,电量过低提醒)。

三.开发者支持

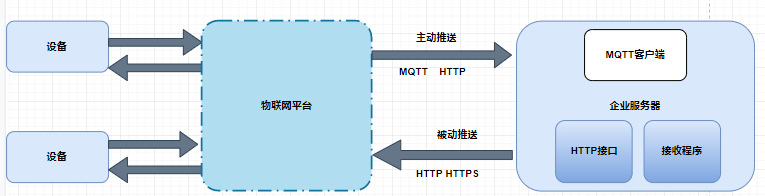

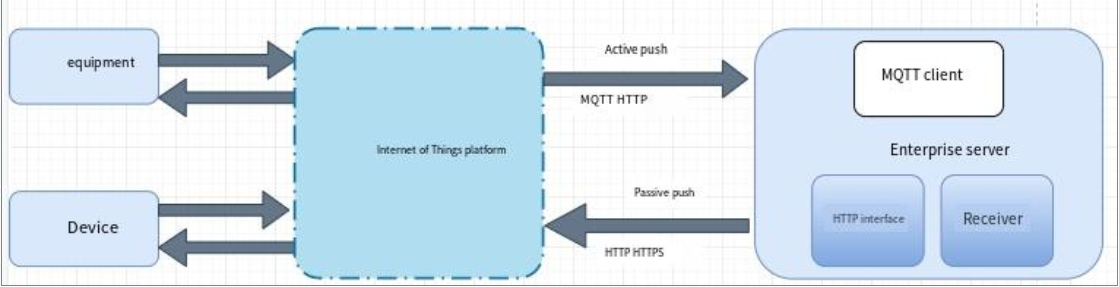

箱行天下平台提供集装箱位置和状态数据。设备数据发送到箱行天下物联网平台后,平台提供主动推送数据(MQTT、HTTP)和被动获取数据(HTTP/HTTPS)两种方式跟用户对接。MQTT推送方式,需要用户端用MQTT客户端订阅平的数据;HTTP推送方式,需要用户端按照本文档的规定开发HTTP接口,平台往该接口推送数据。用户也可以利用平台提供的HTTP接口,定时获取数据。

如下图所示。

3.1 获取用户token

token是箱行天平台的全局唯一接口调用凭据,调用各接口时都需使用token。开发者需要进行妥善保存。token的存储至少要保留70个字符空间。

Token分为userToken和mqttToken,其中userToken用于访问http/https接口;mqttToken用于订阅MQTT推送的数据。

3.2 集装箱数据推送订阅

通过http/https推送数据,用户平台需要提供一个接收数据接口的url地址,箱行天下平台会调用该接口将JSON格式的数据推送过去。

箱行天下平台与用户平台之间传输的数据传输的数据统一采用UTF-8编码,数据时间均用 UTC 时间(比北京时间少8小时)。

3.3 集装箱数据查询服务

用户需要通过接口主动获取集装箱实时数据或历史数据,则需要调用箱行天下http接口,前提条件是,需要先调用用户登录接口获取userToken。

箱行天下平台与用户平台之间传输的数据传输的数据统一采用UTF-8编码,数据时间均用 UTC 时间(比北京时间少8小时)。

四.常见问题汇总

4.1 实时数据问题

1、为什么在实时数据中查询到某个箱号未有上报更新数据?

答:出现集装箱长时间没有更新上报数据的情况可能有以下几个原因:

1.集装箱位于信号较弱或信号干扰的地方。可能由于周围环境或场景的信号限制,例如集装箱在运输过程中,途径高楼、山脉、海上、密集林地等信号较弱或偏远的地方,或集装箱被堆压存放处于长期静止状态等原因,导致无法接收到足够的卫星信号,影响到数据的上报更新。

排查解决:持续关注箱子的移动状态,箱子地点发生转移后,可能会重新恢复上报数据。若地点发生转移后,仍长时间未上报数据,则可能设备存在故障问题,可进行返修更换。

2.设备电量不足。当电池电量低于正常工作所需的水平时,将会影响到设备更新上报数据。

排查解决:(1)干箱设备的电池电量值较低(电子通风器电量值低于3%),需更换新的设备来解决电量不足的问题。(2)冷箱设备的电池电量值较低(冷箱卫士电量值低于10%),可进行冷箱通电打冷,即可对设备进行充电,来解决设备电量不足问题

3.设备故障:设备可能存在故障,导致无法正常工作进行实时数据上报。

排查解决:建议检查一下设备外观是否有损坏或丢失情况、检查设备是否连接正常(冷箱卫士请确认设备DATA灯是否有常亮,或尝试重新拔插电源线启动设备进行排除故障)。若设备存在故障问题,可进行返修更换。

2、为什么实时数据中查找的某个集装箱位置信息与实际位置不相符?

答:显示出不准确的定位信息有以下一些常见原因:

1.集装箱位于信号较弱或信号干扰的地方:可能由于周围环境或场景的信号限制,例如集装箱在运输过程中,途径高楼、山脉、海上、密集林地等信号较弱或偏远的地方,或集装箱被堆压存放等原因,导致无法接收到足够的卫星信号,使得设备GPS定位不准确或失去信号,从而显示不一致的位置信息。也可能在某些地区存在其它无线设备或信号源,如建筑物、树木、高速公路或电力线路等,这些因素可能会产生电磁信号干扰导致设备定位不准确。

排查解决:持续关注箱子的移动状态,箱子地点发生转移后,可能会重新恢复上报数据。若地点发生转移后,仍长时间未上报数据,则可能设备存在故障问题,可进行返修更换。

2.GPS天线未接好:若集装箱是属于冷藏箱,可能由于GPS天线未接好或出现故障,导致无法接收到卫星的定位信息。

排查解决:请检查安装设备的GPS天线是否有正确连接好,建议可以尝试重新拔插GPS天线来进行排除故障。

3.集装箱号与设备号绑定关系错误:如果设备号与集装箱号绑定错误,将导致显示的位置与实际位置不匹配。

排查解决:可通过“箱行天下”平台网页端中 【集装箱管理】—【集装箱管理】页面,通过搜索【箱号】来确认箱号与设备号绑定是否正确。若不正确,请重新解绑修改正确的箱号与设备号关系。

4.设备故障:设备本身可能存在故障,如GPS天线损坏或其它硬件故障,导致其无法准确地获取卫星信号以提供定位信息。

排查解决:建议检查一下设备外观是否有损坏或丢失情况、检查设备是否连接正常(冷箱卫士请确认设备DATA灯是否有常亮,或尝试重新拔插GPS天线、电源线启动设备进行排除故障)。若设备存在故障问题,可进行返修更换。

5.软件版本低:冷箱卫士设备可能由于软件版本较低,导致定位数据信息与实际位置有偏移。

排查解决:在冷机处于开机状态时,可联系技术人员进行设备软件版本远程升级,升级完成即可修复。

若上述排查过程中如有问题,可联系技术团队协助排查处理。

3、为什么在实时数据里没有查询到某个箱号的数据?

答:由于箱号未在箱行天下平台上进行设备号绑定导致未能查询到改箱号实时数据。

排查解决:

(1)可通过“箱行天下”平台网页端中【集装箱管理】—【集装箱管理】页面,通过搜索【箱号】来确认箱号与设备号是否存在绑定关系。

(2)如箱号未存在绑定关系,请点击【导入集装箱】,根据操作提示,进行设备号与箱号的绑定操作。绑定成功后,即可在实时数据页面通过查询箱号获取到集装箱数据信息。

若上述排查操作过程中如有问题,可联系技术团队协助排查处理。

4、安装在集装箱上的设备显示电池电量低应该如何处理?

答:当电池电量低于正常工作所需的水平时,将会影响到设备更新上报数据,建议尽快充电或更换电量充足的设备。

排查解决:

(1)干箱设备的电池电量值较低(电子通风器电量值低于3%),需更换新的设备来解决电量不足的问题。

(2)冷箱设备的电池电量值较低(冷箱卫士电量值低于15%),可进行冷箱通电打冷,即可对设备进行充电,来解决设备电量不足问题。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

5.平台上显示的集装箱信息为什么一直只有基站定位,没有卫星定位?

答:集装箱的定位一直只有基站定位,没有显示卫星定位可能有如下原因:

1.信号屏蔽或不好:可能由于周围环境或场景的信号限制,例如集装箱周围的建筑物、金属结构或其他物体可能会屏蔽GPS信号,导致无法接收到卫星的定位信息。当集装箱无法获取到卫星定位的时候将会采用基站定位的方式来显示集装箱位置信息。

2.GPS天线未接好:冷箱可能由于GPS天线未接好或出现故障,导致无法接收到卫星的定位信息。

排查方式:若集装箱是属于冷藏箱,请检查安装设备的GPS天线是否有正确连接好,建议可以尝试重新拔插GPS天线来进行排除故障。

3.设备故障:设备可能存在故障或损坏,导致无法正常读取温度数据。

排查解决:建议检查一下设备外观是否有损坏或丢失情况、检查设备是否连接正常(冷箱卫士请确认设备DATA灯是否有常亮闪烁)。若设备存在故障问题,可联系技术人员进行返修更换。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

6、冷藏集装箱当前正在通电打冷,为什么实时数据中显示该箱冷机是关机状态?

答:冷藏集装箱可能出现以下几种情况导致冷箱在打冷开机状态下数据显示为关机:

1.电源连接线未接好。

排查解决:确认设备的电源供电是否正常,检查设备电源线是否受损或断开,可以尝试重新拔插电源线启动设备进行排除故障。

2. 设备故障。设备本身可能存在故障(如传感器损坏、电池损坏),导致无法正确读取冷藏箱的当前状态。

排查解决:建议检查一下设备外观是否有损坏或丢失情况、检查设备是否连接正常(冷箱卫士请确认设备DATA灯是否有常亮)。若设备存在故障问题,可进行返修更换

若上述排查操作过程中如有问题,可联系技术团队协助排查处理。

7、冷藏箱在通电打冷状态,但平台的实时数据中未能查看到该冷箱的送回风温度?

答:导致无法读取到冷藏箱内送回风温度的可能原因有如下:

1.冷机型号:冷箱使用的是冷王MP3000或冷王MP4000的冷机机型。部分冷机机型未加装设备转接线将无法直接读取箱内送回风温度。

排查解决:建议检查确认一下冷藏箱使用的冷机型号,若冷机机型是冷王MP3000或MP4000的冷机机型,需根据冷机型号加装对应的设备转接线,安装转接线后需联系技术人员进行远程设备升级即可实现冷藏箱送回风温度的数据读取。设备转接线获取和安装方法可联系技术团队人员进行获取。

2.传感器问题:设备的温度传感器可能出现问题,无法正确读取箱内送回风温度。

排查解决:请检查设备是否正确安装并连接,可以尝试重新拔插线路,确认连接是否断开或损坏

3.设备故障:设备可能存在故障或损坏,导致无法正常读取温度数据。

排查解决:建议检查一下设备外观是否有损坏或丢失情况、检查设备是否连接正常(确认设备DATA灯是否有常亮闪烁)。若设备存在故障问题,可联系技术人员进行返修更换。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

4.2 集装箱管理问题

8、 集装箱更换安装新的设备后,如何在平台上设置新的设备号与箱号的绑定关系?

答:在平台上修改集装箱号与新安装设备号的绑定关系,可以按照以下步骤进行操作:

(1)登录“箱行天下”平台网页端,进入集装箱管理页面。

(2)搜索要更改绑定关系的集装箱号或设备号。

(3)查询到目标集装箱号或设备号后,勾选该集装箱信息,点击【批量解绑】,解绑之前绑定的箱号与设备号关系。

(4)点击【导入集装箱】,下载模板,根据模板内容进行填写并导入到平台,导入成功后,即完成新的设备号与箱号的绑定操作,新的绑定关系则生效。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

9、冷藏箱安装了冷箱卫士后发现设备自动绑定的箱号与实际外观箱号不一致,需如何处理?

答:由于设备读取的是冷箱出厂配置时冷机的箱号,如果冷箱属于改造翻新箱,可能会存在冷机配置的箱号在与实际外观箱号不一致的情况。

排查解决:可通过手动修改设备号与箱号的关系来解决。如果安装设备后查看到设备自动绑定的箱号与实际外观箱号不一致,可通过在箱行天下网页端,集装箱管理页面,查询对应的设备号或箱号,先将设备号与不正确的箱号进行解绑,解绑之后再将设备号与正确的箱号进行注册绑定操作,从而来纠正。

为了设备号与箱号关系绑定关系正确,确保集装箱数据的准确性,防止因读取箱号错误导致后续数据出现问题。建议设备安装完成后,可通过以下方式检查集装箱的数据情况:

(1)登录“箱行天下”公众号中,进入【首页】和【设备管理】页面,查询确认箱号的数据情况,以及核对设备号与箱号的绑定关系是否正确。

(2)登录“箱行天下”网页端平台中,进入【实时数据】和【集装箱管理】页面查询确认箱号的数据情况,以及核对设备号与箱号的绑定关系是否正确。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

10、 集装箱在箱行天下平台上如何设置区分哪些集装箱是在用或停用状态?

在箱行天下平台上可以通过以下操作方式设置分组以区分哪些集装箱是在用或停用状态:

(1)分组设置:点击【集装箱管理】—【集装箱分组】页面,根据集装箱状态属性创建分组:在系统中可创建两个不同的分组(在用分组、停用分组),一个用于存放【在用状态】的集装箱,另一个用于存放【停用状态】的集装箱。将各个集装箱根据其状态属性分配到相应的分组中。

(2)分组命名:为每个分组设置一个标记或名称,清楚地表示该分组包含的是在用或停用状态的集装箱。进行简单明了的文字标识,例如"在用集装箱"和"停用集装箱"。

(3)用户自定义分组:用户还可根据自己的需求创建自定义的分组。用户可以根据集装箱的状态属性,手动将其分配到不同的自定义分组中,以便更方便地管理集装箱。

通过上述操作方式,用户可以灵活地设置分组,帮助清晰地区分哪些集装箱是在用或停用状态,并进行相应的管理和监控。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

11、 如何将指定某个集装箱的数据分享给其它用户查看?

答:在箱行天下平台上,可以通过以下操作方式将指定的集装箱数据通过微信分享给其他用户查看:

(1)进入【实时数据】页面,搜索查找需要分享的箱号

(2)点击【箱号】,在箱号信息展示窗口,点击行程信息右方【分享】,可通过扫码或分享链接方式将集装箱数据分享给其他用户查看集装箱数据。

若上述排查操作过程中如有问题,可联系技术团队协助进一步排查处理。

- 1.Introduction

- 2.Quick Start

- 3.Developer Support

- 4.FAQ

1.Introduction

1.1 Goocontainer

Shipping container tracking provides a range of benefits that positively impact businesses and stakeholders in the logistics industry. Here are the key advantages of container tracking:

Enhanced Visibility: Container tracking offers real-time visibility into the location and status of shipping containers. This visibility allows businesses to monitor and track containers at every stage of the supply chain, enabling better planning, coordination, and decision-making. It improves operational efficiency, reduces transit times, and enhances customer service by providing accurate information about shipment status and estimated arrival times.

Improved Security: Tracking containers helps mitigate security risks. With real-time tracking, businesses can quickly identify any unauthorized access, theft, or tampering of containers. They can take immediate action to prevent losses, initiate investigations, and enhance security measures. Container tracking systems often include features like geofencing and security alerts to ensure the integrity and safety of shipments.

Efficient Resource Allocation: Container tracking optimizes resource allocation. By knowing the precise location of containers, businesses can efficiently allocate labor, equipment, and storage facilities. They can plan and optimize routes, minimize empty container movements, and make better use of available transportation capacity. This reduces costs and enhances overall operational efficiency.

Supply Chain Optimization: Tracking containers allows businesses to optimize their supply chain operations. Real-time visibility into container movements helps identify bottlenecks, delays, or disruptions in the logistics process. This enables businesses to proactively address issues, make timely adjustments, and maintain smooth supply chain flows. Optimization leads to improved delivery times, reduced inventory holding costs, and enhanced customer satisfaction.

Data-driven Insights: Container tracking generates a wealth of data that can be analyzed to gain valuable insights. By analyzing tracking data, businesses can identify patterns, trends, and areas for improvement. They can optimize shipping routes, identify supply chain inefficiencies, and make data-driven decisions. These insights enable continuous improvement and better strategic planning, ultimately leading to cost savings and operational efficiencies.

Risk Mitigation: Container tracking helps mitigate risks associated with transportation and logistics. By monitoring containers in real-time, businesses can anticipate and respond to potential delays or disruptions, such as adverse weather conditions or port congestion. They can take proactive measures to mitigate risks, reduce the impact of unforeseen events, and ensure the smooth flow of goods.

1.2 Our Product

Container Tracking and Reefer Guard produced by Shenzhen ZhongJi Intelligent, are smart container equipment that can read, manage, and monitor various aspects of container data. They are used in conjunction with "Goocontainer" to form a closed-loop IoT system, improving the operational management efficiency of container owners and ultimately increasing enterprise profits.

Shenzhen ZhongJi Intelligent's " Container Tracking " is a type of smart container equipment designed to provide real-time monitoring and data collection for containers. It can be installed at the container's ventilation opening and connected to Shenzhen ZhongJi Intelligent's Goocontainer" platform, providing comprehensive remote monitoring and data analysis.

The main features and functions of the " Container Tracking " equipment include:

Real-time location and motion monitoring: With integrated positioning systems and accelerometers, the Container Tracking " equipment can provide real-time information on the container's position and motion. This allows enterprises to track and monitor the container's precise location at any time and understand its actual status in the supply chain.

Temperature sensor: The " Container Tracking " equipment is also equipped with a temperature sensor that can monitor the temperature around the container. This is particularly important for transporting goods, as it ensures that the goods are transported under suitable environmental conditions.

Data analysis and reporting: By connecting to Shenzhen ZhongJi Intelligent's IoT platform, the data collected by the " Container Tracking " equipment can be analyzed and reported in real time. This data can be used to optimize supply chain operations, improve logistics efficiency, and provide valuable insights and decision support.

The main features and functions of the "Reefer Guard" equipment include:

Temperature and humidity sensor: The " Reefer Guard " equipment is equipped with temperature and humidity sensors that can collect temperature and humidity data inside the container. Temperature and humidity monitoring plays a significant role in cold chain transportation, as it effectively improves the efficiency and intensity of cargo management and reduces the risk of spoilage during transportation.

Alarm and alert functions: The " Reefer Guard " product has alarm and alert functions to help users respond to potential issues in a timely manner. For example, when the temperature or humidity exceeds the set safety range, the product will push alert notifications to the user. This allows users to take immediate action to prevent damage to the goods.

Data analysis and reporting: The " Reefer Guard " product is connected to the "Goocontainer" platform, allowing for the collection, storage, and analysis of transportation data. This data can be used to generate reports and analysis, helping users understand the transportation status, efficiency, and supply chain performance of refrigerated containers

1.3 Data Channel

Our products support two data reporting methods: base station and satellite. The base station method is suitable for use in urban areas or areas with good network coverage. It can wirelessly transmit device data in real-time to the platform database through the wireless network. On the other hand, the satellite method is suitable for remote areas or areas with poor network coverage. It transmits data to the platform via satellite communication, ensuring the stability and reliability of the data.

Our platform database has powerful data management and processing capabilities. It can receive and store data from various smart devices and perform real-time data analysis and processing. Through our user-friendly interface, you can easily access and manage device data, monitor device status, and generate detailed reports and analysis results. Additionally, our platform supports data export and sharing, facilitating data exchange and sharing with other systems or partners.

Our products can meet the needs of businesses and organizations. Whether it's environmental monitoring, logistics tracking, agricultural management, or industrial automation, our solutions can provide reliable data management and analysis support, helping you achieve more efficient and intelligent business operations.

2.Quick Start

2.1 Search by Container Number

The search bar is located in the top left corner of the page. Enter the container number to perform a search. The search function supports fuzzy search, meaning that entering partial keywords of the container number will display dropdown options with results that include the entered keywords. Clicking on an option will navigate to that specific result.

2.2 View Data

In the Real-Time Data menu, search for the container you want to view. Click on the container to display detailed container data in a popup on the left side. This includes the container number, the container's latest position, temperature and humidity information (temperature and humidity curve), refrigerated container refrigeration unit status, the current positioning method of the container, and the container's movement status (stationary/transporting).

2.3 Bind WeChat Account

In the Member Management menu, users can bind their Goocontainer platform account with their WeChat account.

Binding method:

(1) Click the "Bind WeChat" button next to the account.

(2) Open WeChat on your mobile phone and scan the QR code displayed in the popup.

(3) Select a profile picture and nickname.

(4) Complete the binding process.

Unbinding method:

(1) Click the "Unbind WeChat" button next to the account.

(2) Click "Confirm."

(3) Complete the unbinding process.

A Goocontainer account can be bound to a maximum of one WeChat account, and similarly, a WeChat account can be bound to a maximum of one Goocontainer account.

After binding the WeChat account, you can enable WeChat message notifications to receive alarm reminders for container numbers (e.g., high temperature alert, low battery alert).

3.Developer Support

The Goocontainer platform provides container location and status data. After the device data is sent to the Goocontainer IoT platform, the platform offers two ways for users to connect: active data push (MQTT, HTTP) and passive data retrieval (HTTP/HTTPS). In the MQTT push method, the user's endpoint needs to subscribe to the platform's data using an MQTT client. In the HTTP push method, the user's endpoint needs to develop an HTTP interface according to the specifications in this document, and the platform will push data to that interface. Users can also use the platform's provided HTTP interface to retrieve data at scheduled intervals.

3.1 Obtaining User Token

Obtaining User Token is the unique global access credential for the Goocontainer platform. It is required for calling various interfaces. Developers need to securely store the token. The token should be stored in at least 70 characters of space. The token is divided into userToken and mqttToken, where userToken is used for accessing HTTP/HTTPS interfaces, and mqttToken is used for subscribing to MQTT data push.

3.2 Subscription for Container Data Push

For data push via HTTP/HTTPS, the user platform needs to provide a URL for receiving data. The Goocontainer platform will call that interface to push JSON-formatted data. The data transmitted between the Goocontainer platform and the user platform is encoded in UTF-8, and all data timestamps are in UTC time (8 hours behind Beijing time).

3.3 Container Data Query Service

If users need to actively retrieve real-time or historical container data through an interface, they need to call the Goocontainer HTTP interface, with the prerequisite being the userToken obtained from the user login interface in 2.1. The data transmitted between the Goocontainer platform and the user platform is encoded in UTF-8, and all data timestamps are in UTC time (8 hours behind Beijing time).

4.FAQ

4.1 Real-time Data Issues

1. Why is there no updated data for a certain container in the real-time data?

Answer: There could be several reasons why a container has not updated its data for a long time:

The container is located in an area with weak or interfered signals. It could be due to signal limitations in the surrounding environment or scene. For example, if the container is in transit through areas with weak or remote signals such as tall buildings, mountains, seas, dense forests, or if the container is stored in a compressed or stationary state, it may not receive sufficient satellite signals, which affects data updates. Troubleshooting: Continuously monitor the container's movement. If the location of the container changes, it may resume updating its data. If the container still doesn't report data after a location change, there may be a device malfunction, and it should be returned for repair or replacement.

The device has low battery power. When the battery power is below the required level for normal operation, it can affect the device's data updates. Troubleshooting:

• For dry containers, if the battery power is low (less than 3% for the Container Tracking), the device needs to be replaced with a new one to solve the low battery issue.

• For refrigerated containers, if the battery power is low (less than 10% for the Reefer Guard), the container can be connected to power to charge the device and resolve the low battery issue.

Device malfunction: The device may have a malfunction, preventing it from working properly and updating data in real-time. Troubleshooting: Check if the device's exterior is damaged or missing, and verify if the device is properly connected (for the Reefer Guard, check if the DATA light is continuously on). If there is a device malfunction, it should be returned for repair or replacement.

2. Why does the location information of a certain container in real-time data not match the actual location?

Answer: Inaccurate location information can be caused by the following common reasons:

The container is located in an area with weak or interfered signals: It could be due to signal limitations in the surrounding environment or scene. For example, if the container passes through areas with weak or remote signals such as tall buildings, mountains, seas, dense forests, or if the container is stored in compressed conditions, it may not receive sufficient satellite signals, resulting in inaccurate or lost GPS signals and inconsistent location information. There may also be other wireless devices or signal sources in certain areas, such as buildings, trees, highways, or power lines, which can cause electromagnetic signal interference and inaccurate device positioning. Troubleshooting: Continuously monitor the container's movement. If the location of the container changes, it may resume updating its data. If the container still doesn't report data after a location change, there may be a device malfunction, and it should be returned for repair or replacement.

GPS antenna not properly connected: If the container is a refrigerated container, it's possible that the GPS antenna is not properly connected or has a malfunction, resulting in the device not receiving satellite positioning information. Troubleshooting: Check if the GPS antenna of the installed device is properly connected. Try unplugging and re-plugging the GPS antenna to troubleshoot the issue.

Incorrect binding between container number and device number: If the device number is incorrectly bound to the container number, it will result in inconsistent location information displayed. Troubleshooting: Use the "Goocontainer" platform's web interface in the Container Management section to search for the container number and verify if the binding between the container number and device number is correct. If incorrect, unbind the incorrect pairing and rebind the correct pairing.

Device malfunction: The device itself may have a malfunction, such as a damaged GPS antenna or other hardware issues, preventing it from accurately receiving satellite signals for positioning. Troubleshooting: Check if the device's exterior is damaged or missing and verify if the device is properly connected (for the Reefer Guard, check if the DATA light is continuously on). If there is a device malfunction, it should be returned for repair or replacement.

Low software version: Cold box guard equipment may have low software version, resulting in the positioning data information and the actual location offset. Troubleshooting: When the cold machine is in the boot state, you can contact the technical personnel for remote upgrade of the equipment software version.

If there are any issues during the troubleshooting process, contact the technical team for assistance.

3. Why can't I find data for a specific container in the real-time data?

Answer: The lack of real-time data for a container could be because the container number was not bound to a device number on the Goocontainer platform. Troubleshooting:

• Use the "Goocontainer" platform's web interface in the Container Management > Container Management section to search for the container number and verify if it is correctly bound to a device number.

• If there is no binding relationship, click "Container Import" and follow the instructions to bind the device number and container number correctly.

• After the successful binding, the real-time data for the container will be available through the container number search.

If there are any issues during the troubleshooting process, contact the technical team for assistance.

4. How should I handle the situation when the battery level displayed for the device installed on a container is low?

Answer: When the battery level of the device is low, it can affect data updates. It is recommended to recharge the battery or replace it with a fully charged device as soon as possible. Troubleshooting:

• For dry containers, if the battery level is low (less than 3% for the Container Tracking), the device needs to be replaced with a new one to solve the low battery issue.

• For refrigerated containers, if the battery level is low (less than 15% for the Reefer Guard), the container can be connected to power to charge the device and resolve the low battery issue.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

5. Why does the platform only display base station positioning and not satellite positioning for a container?

Answer: If the container's positioning only shows base station positioning and not satellite positioning, it could be due to the following reasons:

Signal shielding or poor signal: It could be due to signal limitations in the surrounding environment or scene. For example, buildings, metal structures, or other objects around the container may block GPS signals, preventing the device from receiving satellite positioning information. In such cases, base station positioning is used to determine the container's location.

GPS antenna not properly connected: For refrigerated containers, the GPS antenna may not be properly connected or could have a malfunction, resulting in the device not receiving satellite positioning information. Troubleshooting: If the container is a refrigerated container, check if the GPS antenna of the installed device is properly connected. Try unplugging and re-plugging the GPS antenna to troubleshoot the issue.

Device malfunction: The device itself may have a malfunction or damage, such as a damaged GPS antenna or other hardware issues, preventing it from accurately receiving satellite signals for positioning. Troubleshooting: Check if the device's exterior is damaged or missing, and verify if the device is properly connected (for the Reefer Guard, check if the DATA light is continuously on). If there is a device malfunction, it should be returned for repair or replacement.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

6. When a refrigerated container is in the process of being powered on for cooling, why does the real-time data display the status of the refrigeration unit as "turned off"?

Answer: A refrigerated container may have the status of the refrigeration unit displayed as "turned off" while it is in the process of being powered on for cooling. This could be due to the following reasons:

Improper power connection: Check if the power supply to the device is functioning correctly. Inspect the power cable for damage or disconnection, and try unplugging and re-plugging the power cable to troubleshoot the issue.

Device malfunction: The device itself may have a malfunction or damage, preventing it from correctly reading the current status of the refrigeration unit. Troubleshooting: Check if the device's exterior is damaged or missing, and verify if the device is properly connected (for the Reefer Guard, check if the DATA light is continuously on). If there is a device malfunction, it should be returned for repair or replacement.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

7. Why can't I view the return air temperature of a refrigerated container in the real-time data when it is in the process of being powered on for cooling?

Answer: The inability to read the return air temperature of a refrigerated container could be caused by the following:

Refrigeration unit model: The refrigerated container may be equipped with a Cold King MP3000 or Cold King MP4000 refrigeration unit. Some refrigeration unit models may require an additional device adapter to directly read the return air temperature. Troubleshooting: Check the refrigeration unit model used in the refrigerated container. If it is a Cold King MP3000 or MP4000 model, an appropriate device adapter must be installed. Contact the technical team for assistance in obtaining and installing the device adapter. After installation, a remote device upgrade may be required to enable the reading of the return air temperature.

Sensor issue: The temperature sensor of the device may have a problem, preventing it from correctly reading the return air temperature inside the refrigerated container. Troubleshooting: Check if the device is correctly installed and connected. Try unplugging and re-plugging the cables to ensure there is no disconnection or damage.

Device malfunction: The device itself may have a malfunction or damage, preventing it from accurately reading the temperature data. Troubleshooting: Check if the device's exterior is damaged or missing, and verify if the device is properly connected (for the Reefer Guard, check if the DATA light is continuously on). If there is a device malfunction, it should be returned for repair or replacement.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

4.2 Container Management Issues

8. After installing a new device on a container, how can I set the new device number and container number binding on the platform?

Answer: To modify the binding relationship between the container number and the newly installed device number on the platform, follow these steps:

1. Log in to the "Goocontainer" platform's web interface and go to the Container Management page.

2. Search for the container number or device number that needs to change the binding relationship.

3. After finding the target container number or device number, select the container information and click "Unbind" to unbind the previously bound container number and device number.

4. Click "Container Import" download the template, fill it out according to the instructions, and import it into the platform. After successful import, the new binding relationship between the device number and the container number will be established and take effect.

If there are any issues during the troubleshooting process, contact the technical team for assistance.

9. After installing Reefer Guard on a refrigerated container, I found that the automatically bound container number does not match the actual container number. How should I handle this?

Answer: The discrepancy between the automatically bound container number and the actual container number can occur if the device reads the container number based on the factory configuration of the refrigeration unit. This can lead to inconsistencies when the refrigerated container is a refurbished or modified unit.

Troubleshooting: To resolve this issue, manually modify the binding relationship between the device number and the container number. If you find that the automatically bound container number does not match the actual container number after installing the device, use the Goocontainer platform's web interface in the Container Management section to search for the device number or container number. Unbind the device number from the incorrect container number and then register and bind the device number to the correct container number to correct the discrepancy.

To ensure the accuracy of the device number and container number binding relationship and the accuracy of container data, it is recommended to perform the following checks after device installation:

• Using the Goocontainer official account, access the "Home" and "Device Management" pages to verify the container number's data and the correctness of the device number and container number binding relationship.

• Log in to the Goocontainer web platform and access the "Real-time Data" and "Container Management" pages to verify the container number's data and the correctness of the device number and container number binding relationship.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

10. How can I set up differentiating between containers in use and containers in a stopped state on the Goocontainer platform?

On the Goocontainer platform, you can set up groups to differentiate between containers in use and containers in a stopped state using the following steps:

(1)Group settings: Go to the "Container Group" page and create groups based on the container status attribute. Create two different groups, one for "in-use" containers and another for "stopped" containers. Assign each container to the respective group based on its status attribute.

(2)Group naming: Set a distinct label or name for each group, clearly indicating whether it contains "in-use" or "stopped" containers. Use clear and concise labels, such as "In-Use Containers" and "Stopped Containers."

(3)User-defined groups: Users can also create custom groups based on their specific needs. Manually assign containers to these custom groups based on their status attribute for convenient management.

By following these steps, users can flexibly set up groups to clearly differentiate between containers in use and containers in a stopped state, allowing for effective container management and monitoring.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.

11. How can I share data for a specific container with other users on the Goocontainer platform?

Answer: On the Goocontainer platform, you can share data for a specific container with other users through WeChat by following these steps:

(1)Go to the "Real-time Data" page and search for the container number you want to share.

(2)Click on the container number, and in the container information display window, click on the "Share" button next to the trip information. You can share the container data with other users by scanning the QR code or sharing the link.

If there are any issues during the troubleshooting process, contact the technical team for further assistance.